Mastering Welding WPS Criteria: Best Practices and Techniques for Quality Welds

In the world of welding, mastering Welding Treatment Specification (WPS) standards is a critical part that straight affects the high quality and integrity of welds. Sticking to these requirements guarantees consistency and reliability in welding end results. Nevertheless, accomplishing excellence in welds goes beyond just comprehending the standards; it involves carrying out finest methods and strategies that raise the craft to a level of precision and ability that sets apart the average from the exceptional. As we browse via the complexities of welding WPS criteria, uncovering essential understandings and strategies for attaining top-tier welds will be vital for welders looking for to succeed in their craft and produce welds that stand the test of time.

Recognizing Welding WPS Requirements

Understanding WPS criteria is crucial for assessors, welders, and engineers associated with welding operations. By complying with WPS guidelines, welders can generate welds that satisfy the required mechanical buildings and architectural stability. Assessors depend on WPS documentation to validate that welding treatments are being followed properly and that the resulting welds are of excellent quality. Engineers make use of WPS criteria to make welding procedures that ensure the toughness and reliability of bonded structures.

Important Tools for Quality Welds

Mastering welding WPS requirements is essential for welders to successfully make use of the vital devices required for producing high quality welds. The kind of welding maker required depends on the welding process being utilized, such as MIG, TIG, or stick welding. Wire brushes and damaging hammers are important for cleansing the weld joint before and after welding to eliminate any type of contaminations that could impact the quality of the weld.

Secret Strategies for Welding Success

To attain welding success, one must grasp the crucial methods necessary for creating Continue high-quality welds. Maintaining a steady hand and a stable welding placement throughout the process is crucial to accomplishing precision and consistency in the welds. By grasping these essential techniques, welders can raise the quality of their job and attain welding success.

Ensuring Conformity With WPS Criteria

Additionally, preserving in-depth records of welding specifications, equipment calibration, and inspection outcomes is important for showing compliance with WPS standards. By carefully adhering to WPS standards, welders can guarantee that their work fulfills the needed high quality degrees and adds to the total success of the welding task.

Troubleshooting Common Welding Issues

To resolve this, ensuring appropriate cleansing of the base metal prior to welding and using the appropriate shielding gas can dramatically reduce porosity. Furthermore, distortion, splitting, and spatter are usual welding difficulties that can be mitigated through appropriate joint prep work, regular warmth control, and picking the suitable welding consumables. By completely recognizing these usual welding issues and their root causes, welders can properly repair troubles and achieve top notch welds.

Conclusion

In final thought, understanding welding WPS criteria calls for a thorough understanding of the standards, making use of crucial devices, and implementing key techniques for successful welds. Ensuring conformity with WPS standards is vital for creating high quality welds and preventing typical welding problems. By complying with ideal techniques and methods, welders can achieve reputable and constant cause their welding projects.

In the world of welding, understanding Welding Procedure Specification (WPS) standards is click site a critical part that straight influences the top quality and stability of welds.When diving into the world of welding techniques, an important element to comprehend is the importance and complexities of Welding Procedure Requirements (WPS) requirements. WPS standards provide a thorough guideline for welding operations, ensuring consistency, high quality, and safety and security in the welding process. The type of welding device needed depends on the welding process being utilized, such as MIG, TIG, or stick welding.Attaining welding success through the proficiency of essential techniques demands an extensive understanding and adherence to Welding Treatment Requirements (WPS) standards.

Mara Wilson Then & Now!

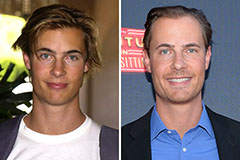

Mara Wilson Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Macaulay Culkin Then & Now!

Macaulay Culkin Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now!